Sustainability – Many Birds, One Stone

‘Two birds with one stone’ – so goes the well-known phrase. But what if you could get more than two birds for a single throw of a stone? How about many birds? And what if these birds were not just flights of fantasy but offered foundational improvements and real upsides, such as increased profitability, recovered capacity and the ability to meet sustainability targets?

Starkly stated sustainability targets such as ‘Net-Zero by 2030’ imply an inherent struggle, and while this may be true in certain arenas, there is a genuine opportunity to achieve environmental goals, automate accountability and improve profitability within manufacturing – all at once.

In this article, we’ll outline exactly how the right capabilities, infused with expertise, can offer a profitable and intelligent pathway to a brighter business and environmental future. Carbon is cash, and reducing your output means retaining capital and growing profitability for the future.

So how is this achieved? Firstly, by fostering a different mindset when conceptualising sustainability measures. Data on utility usage can tell you when you’ve used more or less, but this aggregated data doesn’t have the granularity to explain why. While this is fine for quantifying and reporting on consumption to participate in a carbon exchange, this approach offers no mechanisms to improve these figures. But it doesn’t have to be this way.

Success and Sustainability

Novotek Solutions delivers operational technology with a methodology shaped by a deep knowledge gained in over three decades of experience in IT domains.

We’ve led the way in delivering all our projects to a high, IT-compliant standard. Our solutions are supportable, maintainable, and extensible to keep your operation fit for the future.

In decades past, manufacturers in various sectors have embraced initiatives focused on continuous improvement, aiming to enhance production yields, improve equipment reliability, and minimise waste in materials, labour, and capital. Advanced measurement systems that track metrics like machine downtime and material usage, leading to the establishment of comprehensive factory data infrastructures, all support manufacturers’ end goals.

These systems contextualise raw data by associating it with specific details such as order numbers and product codes. Advanced platforms like Proficy Plant Applications from GE Vernova can integrate data from primary sources like water flow meters into this contextual framework. This practice of collecting detailed data related to core equipment and products results in a robust dataset, which serves multiple purposes:

- Automating Environmental and Compliance Reporting: Using directly measured consumption data to create regulatory reports and calculate incentives.

- Enhancing Carbon Accounting: With varying standards for translating energy consumption into emissions, having granular data allows for flexibility in reporting and adapting to evolving auditing requirements.

- Incorporating Footprint Analysis in Continuous Improvement: Analysing measured environmental factors alongside traditional performance metrics reveals the interplay between operational changes and environmental impact. Comparing a product’s footprint data across different times or locations helps identify significant variations.

This approach allowed a major North American brewer to spot cases where energy consumption varied when all other factors were equal. Measuring energy consumption next to production orders meant it could hunt for root causes through its efficiency management system.

Root causes for relative spikes in usage ranged from inefficient process control algorithms for heating or chilling equipment, inconsistent adherence to recipe setpoints, and poor power management relative to down or idle times. The brewer utilised this insight to make recipes and procedures consistent across all sites.

The result? The brewer met a 5-year energy-savings target in just three years!

Operator Behaviour, Transparency and Compliance

As more firms conclude that a functional information strategy is a critical first step in their sustainability journey, gaining the correct capabilities to gather and process data is essential. In times gone by, multiple data collection regimens assembled reports for different purposes, such as customers or regulators, which led to inconsistencies and undue workload on operators and analysts.

The alternative is a single data platform that serves multiple stakeholders, such as GE Vernova’s Plant Applications. Through a single platform, data is gathered once at an appropriate resolution, and the same data can then be repacked for multiple purposes.

Through this method, operations can automate the management and delivery of regulatory data. Adherence to future carbon passport schemes also becomes a process through which you already have the tools to deal with.

Turning to transparency, increasingly, customers are willing to pay a premium for ‘green’ products, where you can demonstrate a complete genealogy and the positive credentials of your products in total confidence. With a comprehensive data platform in place, you have the power to track and demonstrate the exact journey a product has gone through, from raw materials to finished goods. And that is not to overlook the power of transparent data on your operation.

With greater process visibility, automated with real-time data collection, operations gain the insight required for intelligence decision-making from the shop floor to the top floor. Ingesting and utilising this data with a powerful analytics platform drives an understanding of the cause-and-effect relationships between asset performance and input consumption. This granular data is then fed into corporate EHS and carbon accounting systems, allowing true utility cost profiles to be a part of production costing and planning exercises. Manufacturers then use cross-plant metrics to accelerate best-practice identification and dissemination.

But that’s not where it ends; by embedding analytics into control and visualisation programs, operators can be presented with rich information to drive decision-making at the shopfloor level. By using intelligent systems in this way, operations can also ensure they are not held hostage to the availability of specialists.

Innovative Strategies in Sustainability

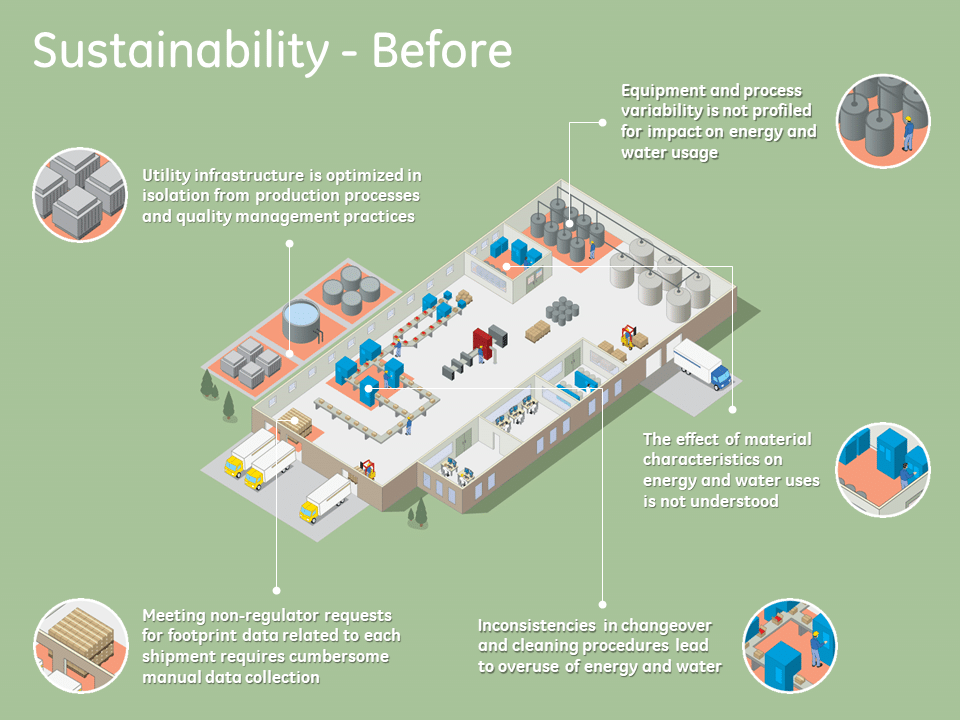

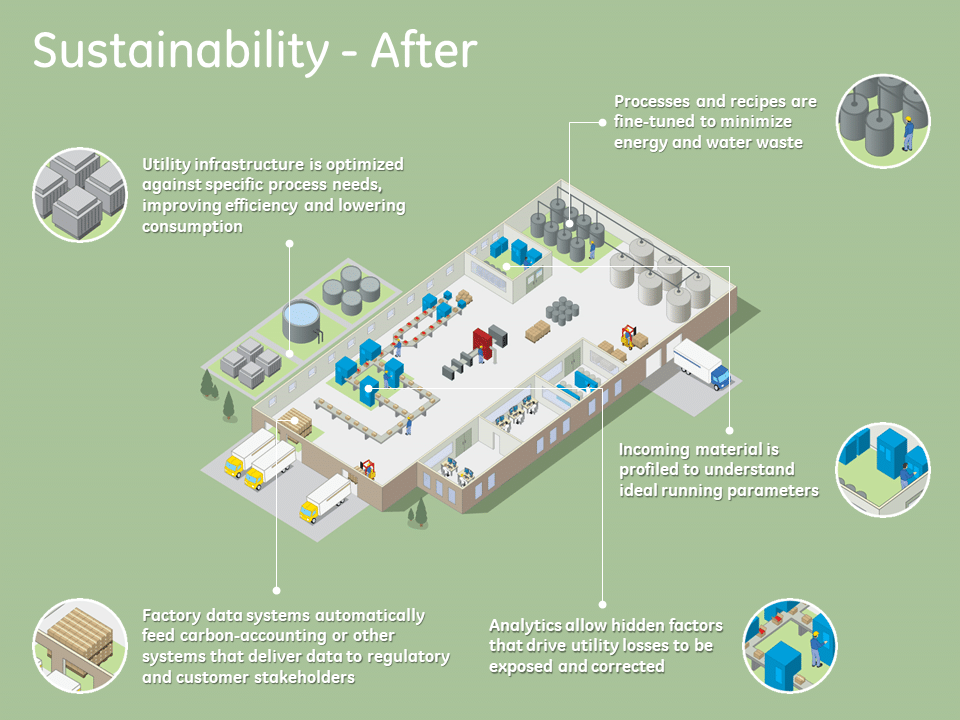

To demonstrate how adopting a manufacturing execution system can offer a ‘many birds for one stone’ solution, we can look at the capabilities and conditions of an operation both before and after implementation.

Before

Without a detailed understanding of how changing utility inputs will affect processes, efforts to be ‘green’ can cause efficiency and material losses while also potentially introducing quality or product safety risks.

The differences between equipment and processes also present difficulties in formulating an effective strategy. With better data collection, all elements of variability can be profiled – including materials used in processes.

After

Data-driven decision-making brings cost, quality and carbon footprint into balance. With the confidence to act backed by information, tuning processes and utility infrastructure ensures sustainability efforts do not compromise operational performance.

The root causes of overconsumption are more easily understood, and strategies to mitigate them can be formulated and actioned at pace.

The ‘Many Birds’ at a Glance

If we’ve demonstrated anything in this article, we hope it’s the broad scope of what’s possible when looking to drive sustainability – and reap the real rewards on offer for manufacturing! Here are the key takeaways of what’s on the table as we progress towards environmental goals:

- Expose hidden relationships between production and sustainability factors.

- A single MES solution provides insight into materials, recipes, assets and processes to find the root causes of the overconsumption of utilities.

- Gain a single source of truth and improve the visibility of your consumption.

- Granular data gathered by the single platform can be packaged, analysed and presented to serve many needs.

- Integrate metrics and analysis to provide additional insight.

- Automating analytics within a single, scalable platform provides value from the shop floor to the top floor and drives fast, accurate decision-making powered by information.

- Automate regulatory compliance and power transparency and traceability.

- Gain competitive capabilities to demonstrate green credentials to customers and other stakeholders.

Last but not least, and in a nutshell, why select Plant Applications from GE Vernova?

- Flexibility in Data Management: The platform can easily link basic time-series data from meters to a wider range of elements like materials, products, and events, all through straightforward configuration.

- Support for Multiple Stakeholders: Plant Applications offers a variety of reporting and analytics capabilities, catering to both internal stakeholders focused on improvement and external stakeholders, ensuring their diverse needs are met.

- Open and Layered Approach: Unlike many sustainability metrics systems that are manual or limited to specific sensors, Plant Applications enhances existing sensor, automation, and software investments, offering a more integrated solution.

Continue the conversation

Do you have any questions about sustainability and manufacturing? Chat to one of our friendly experts to find out more.